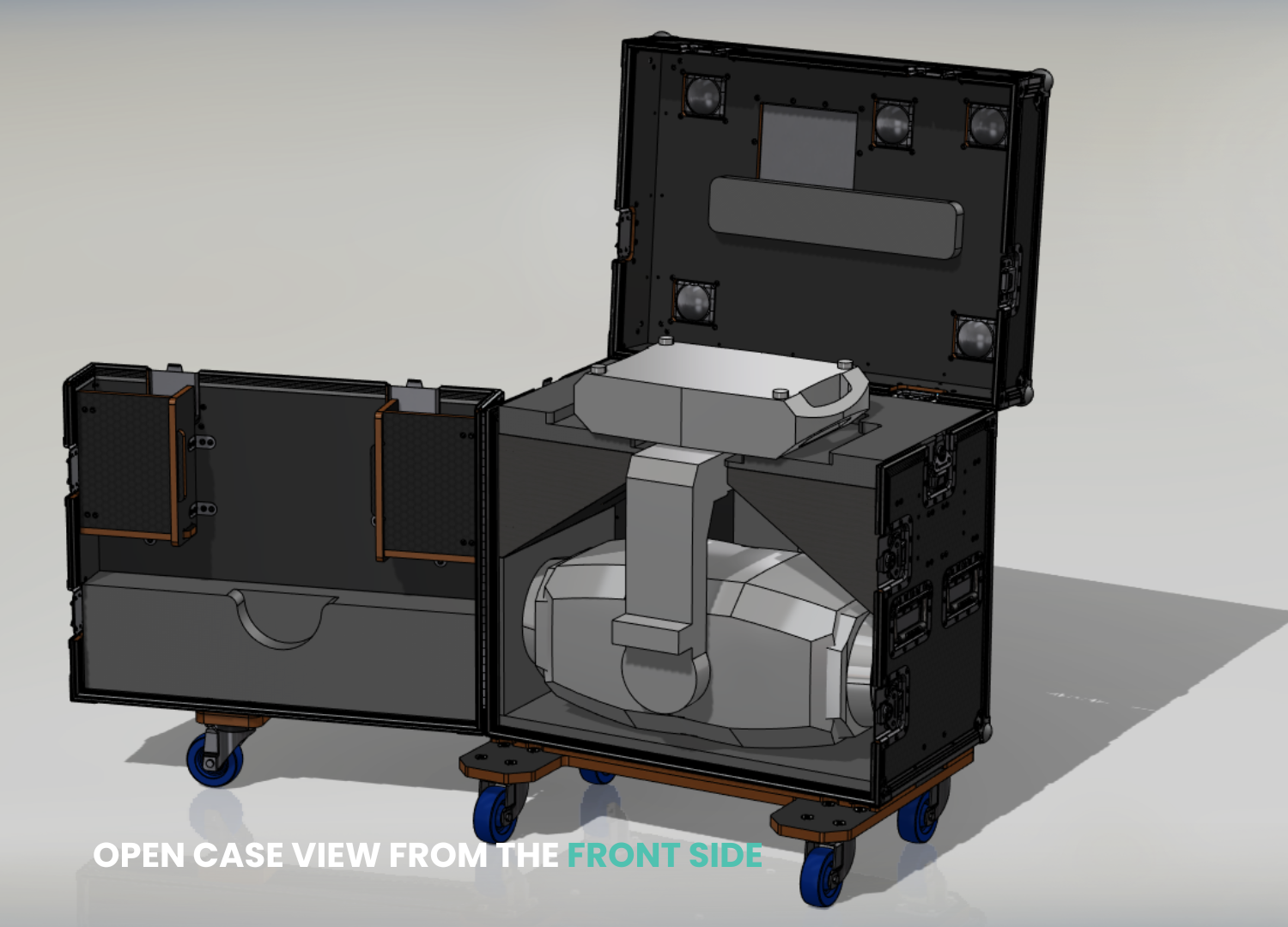

Flight case design isn’t just about protection—it’s also about usability and logistics. When we were approached to create a custom case for the Chauvet Maverick Storm 4 Profile, one of the largest moving head lights in its class, the standard top-loading configuration quickly proved impractical. The fixture’s size, weight, and the way it needs to be handled led us to an alternative approach: a side-loaded road case.

Input Conditions and Design Constraints

The client’s key requirements were clear:

The case had to fit the Maverick Storm 4 Profile with minimal footprint.

It needed to provide safe, repeatable loading and unloading with reduced risk of damage or injury.

Structural durability had to meet touring-grade expectations.

The overall weight and external dimensions should stay within manageable limits for transport and handling.

Our design team also factored in the light’s center of gravity, the accessibility of rigging points, and the use-case scenarios for both indoor and outdoor productions.

The Path to a Side-Loaded Solution

Initial modeling in SolidWorks revealed challenges with vertical loading. The height required for lifting the fixture in and out safely would increase the overall case height significantly, complicating logistics. Additionally, top-loading raised risks of improper handling, particularly in fast-paced environments like festivals and live events.

By shifting to a side-loading design, we eliminated the need for vertical lifting altogether. The light could now be slid in and out using custom-milled runners, padded guides, and foam support that aligned with its frame. This reduced the handling time and the potential for accidental impact or misalignment.

Ensuring Structural Integrity

A side door introduces a different stress profile than top-mounted lids. To ensure structural performance, we reinforced the internal framing around the access door and introduced load-distribution ribs to resist flex during transit. Every latch and hinge was rated for repeated use under rugged conditions. We also ran basic FEA simulations in SolidWorks to assess door flex under load and confirm the frame’s torsional strength.

Corner protectors, recessed hardware, and edge extrusions were carefully integrated to meet ATA standards while maintaining clean aesthetics.

The Importance of This Design in the Industry

Side-loaded cases aren’t new, but they are underutilized in larger fixture logistics. This case sets a precedent for designing around operational workflows, not just equipment dimensions. As moving head lights become more powerful—and larger—designing for ergonomics, efficiency, and safety becomes essential.

For touring companies, rental houses, and production crews, this case offers:

Faster setups and teardowns

Reduced risk of damage during handling

Lower lifting fatigue for technicians

This project exemplifies how thoughtful design, supported by professional CAD workflows, can solve real-world challenges and elevate the standard for road case engineering.