Reverse Engineering

Unparalleled proficiency in bringing innovation to prototypes and existing products.

Software Proficiency

Pricings

Consulting

$50/ hour

Managing

$30/ hour

Execution

$15/ hour

The price listed above is the usual cost of the service. However, depending on the project’s size and complexity, changes could be made. We encourage you to contact our sales team for additional consultation if you would like accurate and comprehensive information catered to your unique needs.

Overview

Taking advantage of the innovative opportunity, our 3D reverse engineering service enables us to make new and better out of the existing parts or products. Our professional engineers use the latest scanning technology and, with the help of special CAD software such as Geomagic Design X, capture and analyze physical objects in a detailed manner to create the correct digital representations.

We decompose old components into sophisticated equipment, we find defects, and we streamline activities. Our holistic nature guarantees that we have been able to replicate perfectly and add some embellishments to meet high functionality and efficiency. It gives the clients the benefit of fewer development cycles, cost reduction, and better management of the product life cycle. Our reverse engineering services cater to your business requirements using legacy assets or come up with new solutions, and trust us to do it.

3D Scanning

We have expertise in the field of 3D scanning and specialize in reverse engineering, where we have self-developed in-house methods of calibration and surface preparation. Our professional team finds the highest scanning speed and density that can be optimized in case of laser scanning, and makes sure that the accuracy is high, where clarity takes precedence. We also incorporate probe scanning of complex components, which saves on the time of post-processing but is equally accurate and clean.

From pumps and compressors to automotive and delicate art objects, we have developed the art of fine-tuning our skills to meet the various geometries of parts. Contact us today, and we can conduct a consultation that is specific to your 3D scanning requirements and make sure that it is accurate and efficient to make your project successful.

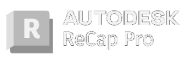

Image to Mesh - Photogrammetry

Launching a new Photogrammetry service, which is a cheaper alternative to conventional 3D scanning. It is remotely conducted, which means that there is no need in terms of physical transport of parts, which lowers the operating expenses. We have worked out detailed SOPs on the capture of images, which are shared with the client to get accurate data. In other cases, we can also take pictures of the subject within the company when necessary.

Due to the use of the highest quality software, such as Autodesk ReCap Photo, RealityCapture, 3DF Zephyr, and Meshroom, we can guarantee high resolution and 3D-printable models without any extra postprocessing. In the case of engineering, post-processing might be necessary in order to achieve high-accuracy surfaces.

We have high-quality control and reverse engineering tools mechanical that ensure clean results, which can be used instantly. It is not difficult to experience the future of 3D modeling. Get in touch with us and receive a specific consultation and realize the maximum potential of photogrammetry in your projects.

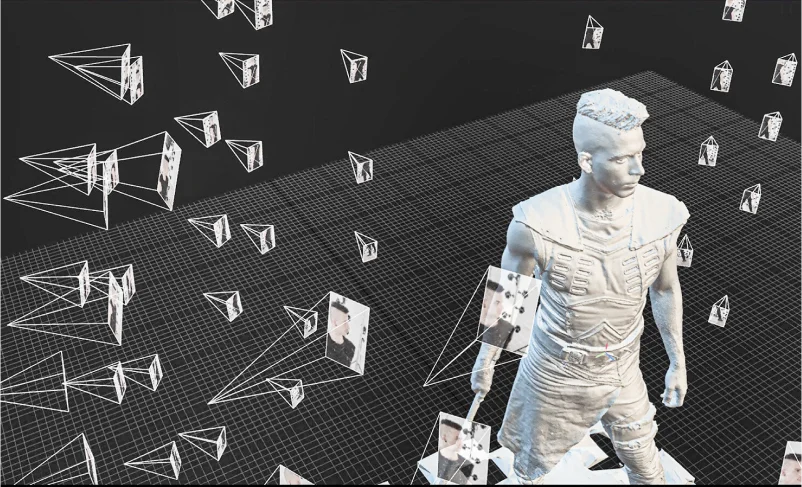

Post-Processing & 3D Modeling

In very precise uses, such as CAM programming, solids and surfaces need to be accurate based on mesh data. Our service will support this need and make sure that it is smoothly integrated into the specific software environment of the client and that the optional model trees support the increased organisation. In automotive and art/architecture, we are experts in producing Class-A surfaces of flawless quality. With the use of industry-leading software, including Geomagic Design X, Geomagic Wrap, Autodesk ReMake, and PolyWorks, as well as being integratively compatible with the most popular CAD software, including SolidWorks and Inventor, or using standard options like Fusion 360, we are confident in the accurate modeling to the needs of a variety of applications.

We do this through Comparative Analysis, Dimensional Checks, and refinement to ensure loyalty to the scan data and discard any extraneous mesh noise to achieve the best results. You can see the accuracy and dependability of our Mesh Post-Process Modeling service today when you contact us and have the specific requirements of your business needs handled.

Simulation, Analysis & Testing

Reliability, safety, and quality are the most important requirements of high-performance industries such as automotive and OEM. Reverse engineering provides extensive solutions to ensure that reconstructed parts perform well.

We perform material testing and selection, and stress, thermal, and fatigue testing by means of Finite Element Analysis, to guarantee the robustness and durability (READ MORE). The 3D mechanical reverse engineering and printing service that we offer checks the physical interactions of the moving parts, and manufacturability analysis checks the smooth integration into production processes.

As the foundation block of the reverse engineering processes, this service has been providing our clients with full solutions to their products, hence the confidence they have in their products. Get in touch with us today by consulting us and take your reverse engineering projects to new levels of excellence.

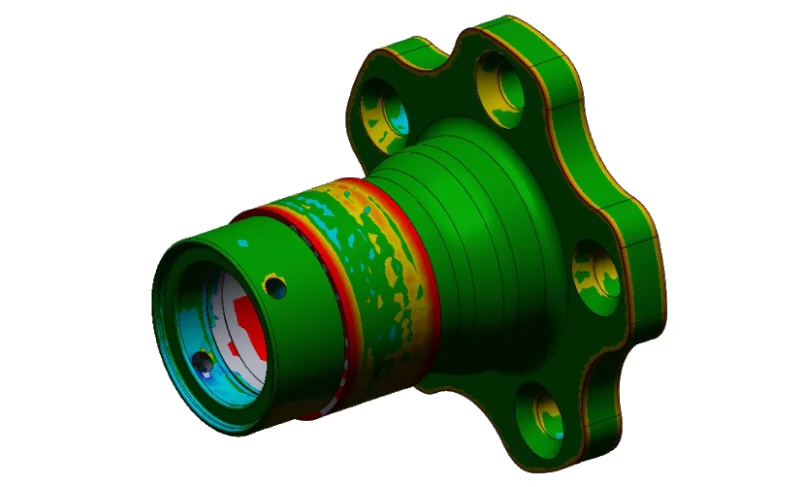

Case Studies

In a recent project, an automotive company aimed to reverse engineer an electric vehicle (EV) drive unit to optimize its design. Using high-resolution 3D scanning and photogrammetry, detailed geometrical data was captured, generating a dense point cloud of the unit. This data was imported into Geomagic software, where a high-quality mesh model was created and converted into a parametric CAD model. Key features such as mounting points and gear assemblies were meticulously modeled and validated.

Subsequent structural and thermal analyses identified areas for design improvements, leading to enhanced structural integrity and thermal efficiency. Prototyping confirmed these enhancements, demonstrating significant cost savings and reduced design cycle time. This project highlighted the effectiveness of combining advanced 3D scanning and CAD conversion technologies with detailed engineering analysis to drive innovation in the automotive industry.

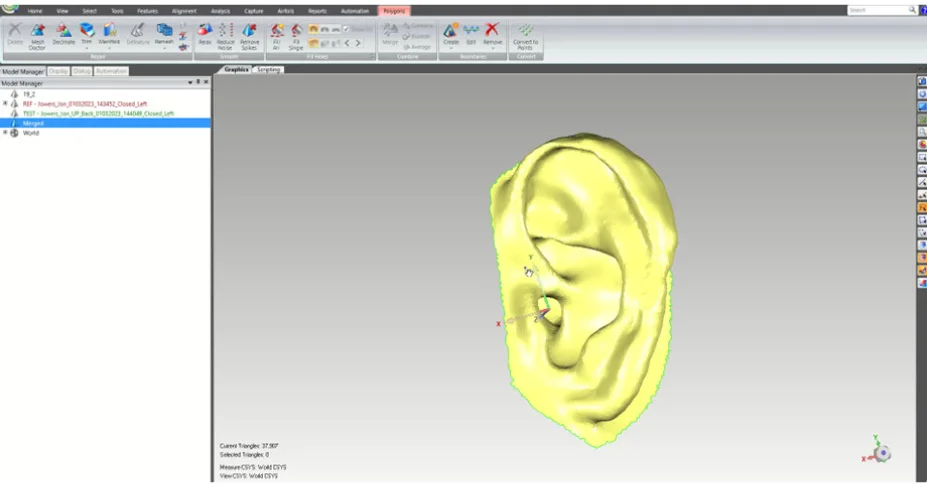

In a recent case study, an audiology company aimed to reverse engineer human ear geometry to improve custom-fit ear devices. Using high-resolution 3D scanning, detailed ear geometrical data was captured, generating a precise point cloud. This data was imported into Geomagic Design X, where it was converted into a detailed mesh model and then into a parametric CAD model.

One significant aspect of the project was developing an efficient process to minimize execution time for economic viability. By optimizing scanning protocols and leveraging Geomagic’s advanced features, the team reduced the time required for data processing and model creation. The resultant CAD models provided an accurate representation of ear geometry, enabling the production of custom-fit devices with improved comfort and performance. This streamlined process not only ensured high-quality outputs but also reduced costs, making it a scalable solution for large-scale production in the audiology industry.

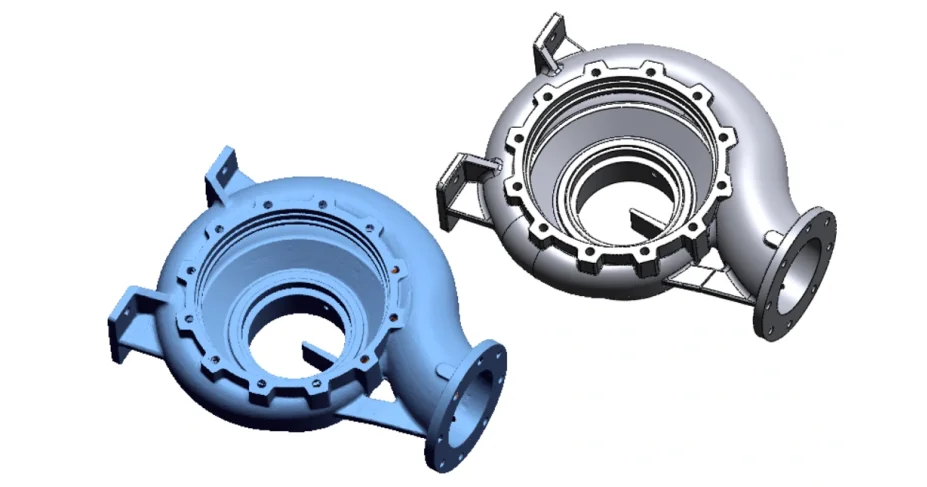

To reverse engineer old centrifugal pump housings and ensure their performance matches original specifications, the process began with dismantling the pumps and using 3D scanning technology to capture detailed measurements. These measurements were then imported into CAD software to create accurate 3D models of the housings. Post-modeling analyses involved running Computational Fluid Dynamics (CFD) simulations to predict performance metrics such as flow rates and pressure heads.

To validate these predictions, physical prototypes of the new housings were tested under various operational conditions, and their performance was compared to the original pumps. Key parameters like efficiency, vibration, and noise levels were meticulously analyzed to confirm that the new models replicated the original pump's performance accurately, ensuring their reliability as replacements.

In a case study focusing on the development of breast prosthetics for breast cancer survivors, a medical device company aimed to enhance the fit and comfort of custom breast prostheses using photogrammetry. This non-invasive technique involved capturing high-resolution images of the chest area from multiple angles to generate a detailed 3D model. Specialized medical CAD software was then employed to convert these photogrammetric models into precise parametric CAD models.

The project prioritized streamlining the workflow to minimize execution time, which was essential for reducing production costs and patient wait times. By optimizing the image capture and modeling processes, the team efficiently produced custom prosthetics tailored to each patient’s unique contours. The resultant prosthetics offered a natural look and feel, significantly improving the quality of life for breast cancer survivors.

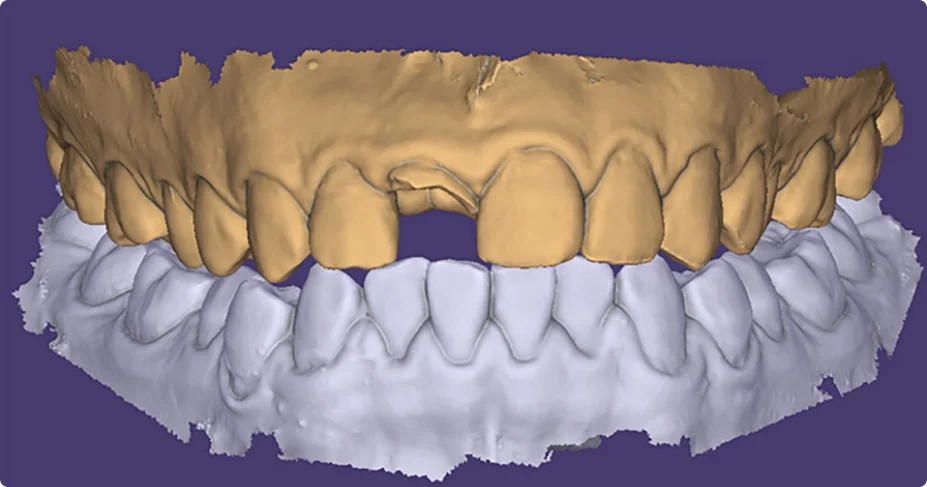

In a case study involving reverse engineering for a dental application, a dental lab aimed to improve the accuracy and fit of custom dental implants. Utilizing high-resolution 3D scanning, the lab captured detailed geometrical data of dental impressions, creating precise point cloud data of the patient’s dental structure. This data was imported into specialized dental CAD software, where it was transformed into a detailed mesh model and subsequently converted into a parametric CAD model.

One of the critical aspects of this project was developing a streamlined process to minimize execution time for economic reasons. By optimizing the scanning protocols and utilizing the advanced features of the dental CAD software, the team significantly reduced the time required for data processing and model creation. The resultant CAD models provided highly accurate representations of the dental impressions, enabling the production of custom dental implants with improved fit and comfort. This efficient workflow not only ensured high-quality outputs but also reduced costs, making it a scalable solution for the dental industry. The project demonstrated the potential of advanced 3D scanning and reverse engineering technologies in enhancing the precision and efficiency of custom dental applications.

Related Services

Design for Manafacturing

Through meticulous analysis and simulation, potential challenges are identified early, allowing for proactive solutions. Our tailored approach minimizes production costs while maximizing performance and safety. Clients benefit from innovative, streamlined designs that enhance operational efficiency, driving success in their industries.

Computer Aided Manufacturing

Offering comprehensive solutions from toolpath generation to machine simulation, our CAM services are tailored to your specific requirements. Experience increased productivity, reduced lead times, and enhanced quality control with our CAM services, driving success in today’s competitive manufacturing landscape.

Simulation

With state-of-the-art tools and methodologies, we provide actionable insights to enhance product functionality, efficiency, and reliability. Whether it’s predicting behavior under real-world conditions or validating design choices, our simulation services empower clients to make informed decisions, and achieve superior results.

Drafting

Delivering precision and compliance, we adhere to esteemed international standards like ANSI, ISO, DIN, ASME, BS, and JIS in our CAD Drafting service. Utilizing industry-leading including AutoCAD, Inventor, SolidWorks, CATIA, Revit, and Tekla Structures, we cater to diverse industries with tailored requirements.

Contact Us

Send us an email @ info@keyway.com.pk using below form and/or set up a free consultation right from our website.

Book a free Consultation

If you have any questions, you think are best answered in an in-person meeting or would like to schedule a session with out experts to know how we can solve your problems, feel free to set up a meeting with us!