Flight case design is much more than just the equipment protection on transit. A professionally designed case should also boost the usability, a shorter setup duration, and safe working conditions in the professional touring or live event setting. When our team was invited to create a custom form of transport to support the Chauvet Maverick Storm 4 Profile, one of the largest and most powerful moving head fixtures in its category, it was clear right away that the creation of a standard top-loading case would be introducing several unnecessary complications. To solve these issues, it was necessary to think about a solution based on the principles of Flight Case Design and Road Case Engineering.

Maverick Storm 4 Profile is a very heavy and large piece of equipment and is usually utilized in intensive Stage Lighting like concerts, festivals, and other large-scale productions. The top-loading standard designs are mostly based on vertical lifting that is not very efficient and risky when handling such a large scale of fixtures. Instead of tailoring the workflow to the case, the current project was dedicated to tailoring the case to real-world operational requirements, which is becoming a philosophy very necessary in Live Event Production and professional Product Design.

Input Conditions and Design Constraints

The client had a well-defined list of requirements that would determine the direction to take in the design before any modelling or prototyping was done. These ensured that the case would be feasible to touring crews, rental houses and production companies that depend on efficiency, durability and safety.

The client’s key requirements were clear:

The case had to fit the Maverick Storm 4 Profile with minimal footprint.

It needed to provide safe, repeatable loading and unloading with reduced risk of damage or injury.

Structural durability had to meet touring-grade expectations.

The overall weight and external dimensions should stay within manageable limits for transport and handling.

The design team also carried out an in-depth investigation into the actual needs of the client besides what the client had mentioned. The location of the center of gravity, ease of rigging points and the manner in which technicians interact with moving head lights are some of the factors that were critically considered during load-ins and load-outs. These will be important in Stage Lighting logistics, where physical fatigue and time pressure may enhance the risks of errors. With these considerations at the outset, the project was highly correlated with the best practices of Road Case Engineering and user-focused Product Design.

Evaluating Traditional Top-Loading Limitations

First concept development was on traditional top-loading case geometries. In Solid Works Design, it was found very quickly that there were difficulties in vertical loading of such a size of a fixture. To move the Maverick Storm 4 Profile safely in and out of the case, there would be a requirement of a lot of vertical clearance, which would raise the overall height of the case. This increased height would make packing of the truck, storage capacity and on site maneuverability (logistical issues in Live Event Production) difficult.

Ernomic risks were also brought about by top-loading. The fact that the heavy fixtures are raised up in the air, increases the chances of not using it properly, especially during the situations when there are several fixtures being deployed at the same time. In festival and touring applications typical of Chauvet Professional systems, it is of utmost importance to minimize the lifting forces that are not required to ensure safety of technicians. These results confirmed that access should be re-thought in its entirety, not optimized to make a system that is fundamentally inefficient.

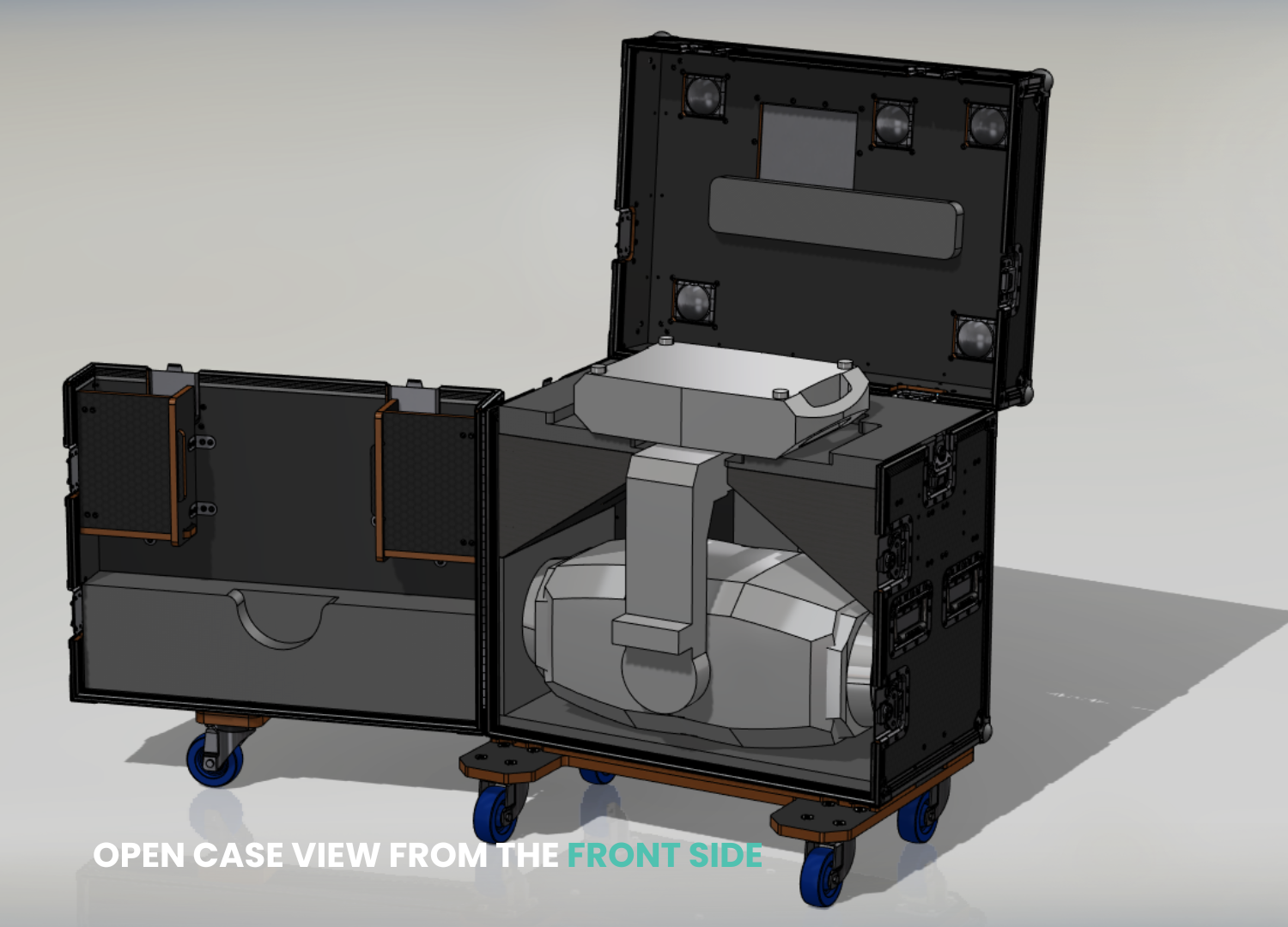

Transitioning to a Side-Loaded Solution

This move to incorporate a side loaded design was a turning point in the design process. Rather than making the fixture move up and down the case was made to enable the loading and unloading of the light horizontally and this avoided the most physically demanding part of the task of handling the light. This design is close to the current Flight Case Design, which emphasizes more and more on ergonomics and efficiency of workflow.

The main characteristics of the side-loaded design will be:

Horizontal sliding access which removes vertical lifting.

Specially-milled runners which direct the position of the fixture.

Padded alignment aids in the prevention of lateral movement.

Foam supports are made to suit the frame of the furniture and weight distribution.

This was a very effective design in regard to saving handling time; it, also reduced the chances of an accidental hit or misalignment. The fact that crews can deploy fixtures in a brief time and safely is a significant operational advantage to Live Event Production crews who face tight schedules. The design in which the side is loaded also guarantees that the position of the fixture is always the same whenever the item is packed, which also adds to the idea of repeatability, which is an essential objective in professional Road Case Engineering.

Structural Considerations and Reinforcement Strategy

Although there are obvious ergonomic advantages of side-loaded access, it places another structural stress pattern in comparison to top-mounted lids. The large side door should withstand frequent opening periods, vibration during transportation and transfer of weights when the cases are placed atop each other. These issues demanded a proper structural planning and strengthening to face them.

Design solutions put in place structurally:

Strengthening of internal framing by the side access door.

Load-distribution ribs to withstand flex when transporting.

Touring-rated heavy-duty hinges and latches.

Very stiff edges on doors to ensure long-term alignment.

Simple solids finite element analysis (FEA) simulations were performed with SolidWorks Design in order to verify these design decisions. Under these simulations, the deflection of doors underweight was evaluated and the rigidity of the torsional type was proven in the overall frame. Other safety-related features were incorporated so that the final product would comply with ATA style standards but retain the appearance of clean lines typically found on high-end Flight Case Design.

Practical Benefits for the Industry

Even though side-loaded have been so far restricted to niche applications, they are still not exploited in large moving head fixtures that obviously have their practical advantages. As is shownwith this project; with a revaluation of the access orientation, much can be done to increase usability without reducing the durability or protective performance a professional road case is supposed to deliver. The requirement of transport solutions that are ergonomically optimized is becoming more and more critical to the industry as the stage lighting fixtures continue to grow in size, weight, and output.

There are also practical benefits in the side-loaded case design: faster assembly and dismantling of the case in the field, less damage during the assembly process through awkward lifting and handling, and physical strain and fatigue to technicians and crew members. The design is more consistent with the real-life operational parameters of working conditions on tours, in rental warehouses, and on production floors by enabling the loading and unloading of the fixture to be achieved at a lower working height.

In the case of touring companies, rental houses and production teams that apply the Chauvet Professional fixtures, the strategy will ensure safer working processes and effective logistics. It is a constructive development of designing cases based on how equipment is being used and deployed, as opposed to just how it fits in a container. Such an attitude towards its users is the main focus of modern product design and road case engineering, which focuses on ergonomics, efficiency, and long-term durability in addition to protection.

Conclusion: Elevating Road Case Engineering Through Thoughtful Design

The given project shows that carefully considered engineering and professional CAD processes can turn an apparently straightforward issue into an innovative opportunity. The design is able to provide quantifiable advantages in safety, efficiency, and usability, by abandoning a conventional top-loading concept and adopting a side-loaded design. The ultimate case with the help of SolidWorks Design, structural analysis, and real-world workflow factors is going to raise the standards of transport solutions in the Live Event Production. After all, this side-loaded maverick Storm 4 Profile case with Chauvet marks the future of Flight Case Design. It proves that when ergonomics, logistics, and structural performance are viewed as a complex, road case engineering can become more than a protection, it can be also a part of the production process itself.