Computer Aided Manufacturing (CAM)

Precision-driven manufacturing solutions, streamlining your production process for unparalleled efficiency and quality.<span data-metadata="">

Software Proficiency

Pricings

Consulting

$50/ hour

Managing

$30/ hour

Execution

$20/ hour

The pricing displayed above represents the average rate for the service rendered. However, variations may occur based on the complexity and scale of the project. For precise and detailed information tailored to your specific requirements, we encourage you to reach out to our sales team for further consultation.

Overview

In modern manufacturing, efficient CAM programming and nesting services are essential for optimizing production workflows and maximizing resource utilization. Specializing in CAM programming and nesting, we provide tailored solutions to meet specific industry needs, ranging from CNC machining to sheet metal fabrication.

Industries such as automotive, aerospace, and furniture manufacturing extensively utilize our CAM and nesting services to streamline production processes. Leveraging leading software such as Mastercam, Siemens NX CAM, and SigmaNEST, we ensure precision and reliability in our programming and nesting solutions.

With our in-house developed methods and practices, we focus on enhancing efficiency and minimizing material wastage. Contact us today for expert consultation on optimizing your manufacturing processes through our CAM and nesting services.

Nesting

With a deep understanding of materials ranging from plywood to metals and foams, our nesting services are tailored to optimize material usage for each specific material type.

Leveraging our in-house developed methods, we efficiently track and repurpose leftover offcuts to maximize material utilization and minimize waste. Our expertise extends across various manufacturing methods, including machining, water jet cutting, and laser cutting, ensuring precise and efficient nesting solutions for diverse production needs.

Specializing in leading nesting software such as Pronest and OptiNest, we guarantee accuracy and reliability in our nesting processes. Whether you're in the furniture industry or metal fabrication, our nesting services are designed to enhance operational efficiency and cost-effectiveness. Contact us today for expert consultation and discover how our nesting solutions can streamline your manufacturing processes while reducing material waste and costs.

G-Code Generation

In our G-code generation services, we meticulously consider various factors to ensure optimal machining outcomes. This includes optimizing toolpaths, selecting appropriate cutting tools, defining feed rates and speeds, setting up workpieces accurately, simulating toolpaths for error detection, and customizing G-code output for specific CNC machine controllers.

We specialize in generating G-code for a wide range of machines, including milling, turning, laser cutting, and 3D printing equipment. Our expertise extends to handling diverse materials and complex geometries, ensuring precise and efficient machining operations.

Choosing an expert like us for G-code generation offers several benefits, including reduced machining time, minimized tool wear, enhanced surface finish, and improved overall productivity. By leveraging our proficiency in G-code programming, clients can optimize their manufacturing processes, minimize errors, and achieve superior machining results.

Custom Feature Recognition

Feature recognition in CAM packages is the process of identifying geometric features within a CAD model to automate the creation of machining operations. This significantly enhances efficiency by reducing manual programming time and ensuring consistent machining strategies. Our customized feature recognition service tailors this process to your specific needs, enabling the software to recognize unique or specialized geometric features pertinent to your manufacturing processes.

We customize feature recognition by defining custom features, adjusting recognition algorithms, and integrating specific machining strategies. Additionally, we develop user-defined libraries and automate workflows through custom scripts and macros. Our service also includes implementing a feedback mechanism to continuously improve recognition accuracy based on user adjustments.

By aligning CAM processes with your unique requirements, our customized feature recognition service increases productivity, reduces programming time, and enhances machining accuracy.

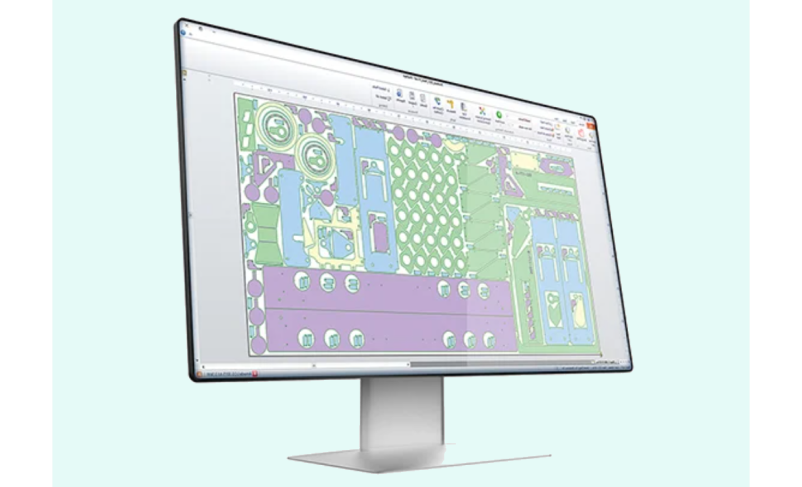

Tool Crib Design

Our tool crib design service ensures your machining operations run smoothly and efficiently. We provide comprehensive tool inventory management, tracking each tool’s specifications, status, and usage history. We optimize tool setup and selection, ensuring the right tools are always ready for specific tasks.

Our service includes organizing the tool crib for easy access and quick changes, reducing setup times and enhancing operational efficiency.

By integrating with your CAM software, we automate tool selection and setup, streamlining your processes. This service offers several benefits, including improved efficiency through reduced downtime and faster production cycles, minimized errors by ensuring the correct tools are used, cost savings from extended tool lifespan and reduced replacement needs, and enhanced productivity through smoother and more reliable machining operations.

Tech. Database Development

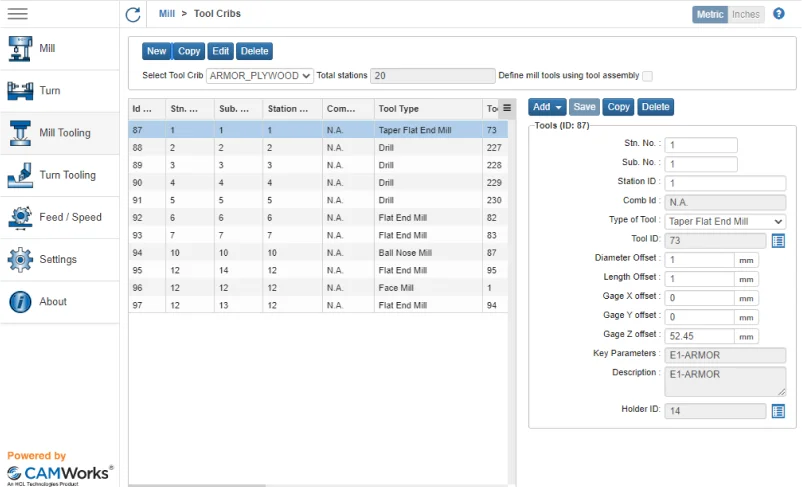

Our tech database development service encompasses the meticulous setup, modification, and optimization of essential technical databases crucial for efficient CAM operations.

Initially, we establish a comprehensive database tailored to your manufacturing needs, incorporating detailed specifications for tools, materials, and machining parameters. Additionally, we specialize in fine-tuning and optimizing existing databases to enhance performance and productivity. By leveraging our expertise, clients benefit from streamlined workflows, reduced setup times, and improved machining accuracy.

Whether it's setting up a new database or refining an existing one, our services ensure that your CAM operations are optimized for peak performance. Contact us today for expert consultation and take your manufacturing processes to the next level.

Reducing Material Waste

At our core, we're dedicated to pioneering innovative methods to reduce material waste in manufacturing. Through relentless research and development, we've devised a cost-effective approach to track and repurpose remnants generated during cutting processes, ensuring maximum material utilization.

Moreover, beyond conventional optimization techniques, we're exploring the integration of AI and machine learning to predict and mitigate material wastage even before the manufacturing process begins. By harnessing predictive analytics, we aim to revolutionize design practices and minimize waste from the outset.

Partnering with us means leveraging these cutting-edge solutions to optimize efficiency, minimize costs, and enhance sustainability. Join us in embracing the future of manufacturing, where waste reduction isn't just a goal but a tangible reality.

Related Services

CAD/CAM Automation

From programmed, parametric 3D models to batch processing and machine optimization, we optimize every aspect of your CAD and manufacturing operations. By automating repetitive tasks and eliminating manual intervention, we help you reduce errors, accelerate turnaround times, and achieve cost savings.

Design for Manufacturing

Through meticulous analysis and simulation, potential challenges are identified early, allowing for proactive solutions. Our tailored approach minimizes production costs while maximizing performance and safety. Clients benefit from innovative, streamlined designs that enhance operational efficiency, driving success in their industries.

Simulation

With state-of-the-art tools and methodologies, we provide actionable insights to enhance product functionality, efficiency, and reliability. Whether it’s predicting behavior under real-world conditions or validating design choices, our simulation services empower clients to make informed decisions, and achieve superior results.

Drafting

Delivering precision and compliance, we adhere to esteemed international standards like ANSI, ISO, DIN, ASME, BS, and JIS in our CAD Drafting service. Utilizing industry-leading including AutoCAD, Inventor, SolidWorks, CATIA, Revit, and Tekla Structures, we cater to diverse industries with tailored requirements.

Contact Us

Send us an email @ info@keyway.com.pk using below form and/or set up a free consultation right from our website.

Book a free Consultation

If you have any questions, you think are best answered in an in-person meeting or would like to schedule a session with out experts to know how we can solve your problems, feel free to set up a meeting with us!