In today’s manufacturing industry, CNC laser cutting has emerged as one of the most efficient and precise methods for shaping a wide range of materials. By combining Computer Numerical Control (CNC) technology with the power of laser beams, manufacturers can create intricate parts with exceptional accuracy and speed.

Whether it’s sheet metal, plastics, composites, or even wood, CNC laser cutting offers a level of detail and efficiency that is difficult to achieve with traditional cutting methods.

What is CNC Laser Cutting?

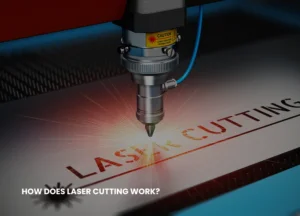

CNC laser cutting is a fabrication process that uses a high-powered laser beam, directed by CNC controls, to cut materials into precise shapes and patterns. The CNC system ensures the laser follows exact programmed paths, allowing for repeatable, high-quality results.

The process works by focusing a laser beam onto the surface of the material, heating it to the point of melting, burning, or vaporizing. Pressurized gas, such as oxygen or nitrogen, is often used to blow away molten material, leaving clean and smooth edges.

Advantages of CNC Laser Cutting

CNC laser cutting offers several advantages that make it a preferred choice for manufacturers:

High Precision – Cuts are accurate to fractions of a millimeter, ideal for complex geometries.

Minimal Material Waste – Narrow kerf widths and nesting optimization save costs.

Versatility – Can work on metals, plastics, ceramics, composites, and more.

Fast Turnaround – High cutting speeds reduce production lead times.

Clean Edges – Eliminates or reduces the need for secondary finishing.

Applications of CNC Laser Cutting

CNC laser cutting is widely used across industries:

Sheet Metal Fabrication – For enclosures, brackets, and industrial components.

Architectural Panels – Decorative facades, signage, and custom patterns.

Automotive Parts – Precision metal cutting for vehicle components.

Aerospace Components – Lightweight, high-precision parts.

Custom Manufacturing – Prototypes, artistic designs, and one-off parts.

Design Considerations for CNC Laser Cutting

When designing parts for CNC laser cutting, it’s important to consider:

Material Thickness – Different lasers have varying power limits.

Kerf Width – Ensure tolerances account for the narrow cut width.

Heat-Affected Zone (HAZ) – Adjust designs to minimize warping.

Nesting Optimization – Arrange parts efficiently to reduce scrap.

At KEYWAY, we work with clients to prepare optimized CAD/CAM files that account for these factors, ensuring cost-effective and efficient production.

Why CNC Laser Cutting Matters

In a competitive manufacturing environment, CNC laser cutting is more than just a fabrication method—it’s a strategic advantage. Its ability to deliver precision, speed, and flexibility makes it a vital tool for industries looking to produce high-quality products while controlling costs.

Conclusion

CNC laser cutting continues to revolutionize manufacturing by enabling designs that were once impossible to achieve at scale. With the right design and production approach, it can drastically improve efficiency and product quality.

Whether you need custom sheet metal parts, industrial components, or decorative panels, CNC laser cutting offers the precision and flexibility your projects require.