CAD/CAM Automation

Boost your production line to transform design and manufacturing processes with greater accuracy and efficiency.

Software Proficiency

Pricings

Consulting

$50/ hour

Managing

$35/ hour

Execution

$25/ hour

The price listed above is the typical cost of the service. However, depending on the project’s size and complexity, changes could be made. We encourage you to contact our sales team for additional consultation if you would like accurate and comprehensive information suited to your unique needs.

Overview

Automation is crucial in simplifying the CAD and CAM operations, improving efficiency, and minimizing errors. Repetitive tasks such as drafting, dimensioning, and geometry calculation can be performed by automation in CAD.

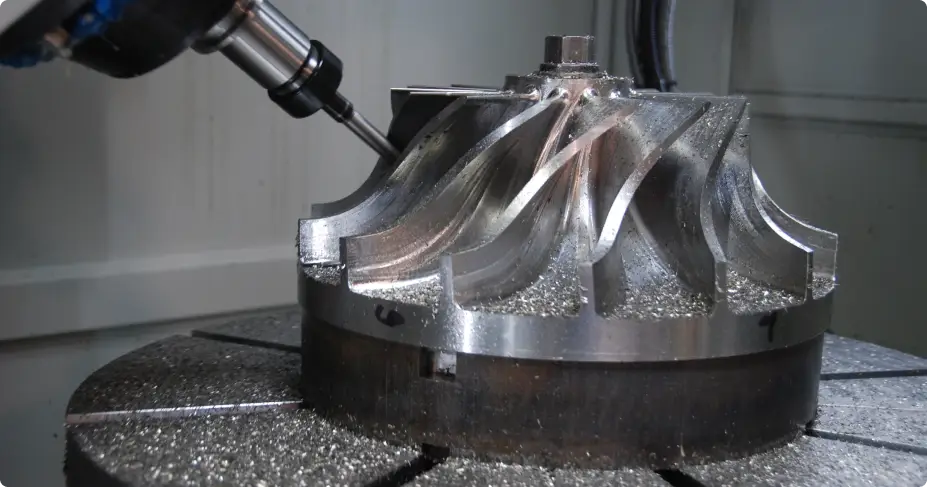

Likewise, automation can also be used to optimize the toolpath, tool choice, and machining in CAM. The CAD CAM automation helps in scripting, macros, and custom plugs, and makes it possible to process a set of tasks in batch and utilize templates to create a set of designs. In the case of CAM, automation is a process of setting the best cutting parameters, creating a toolpath, and connecting to a CNC machine to facilitate manufacturing processes.

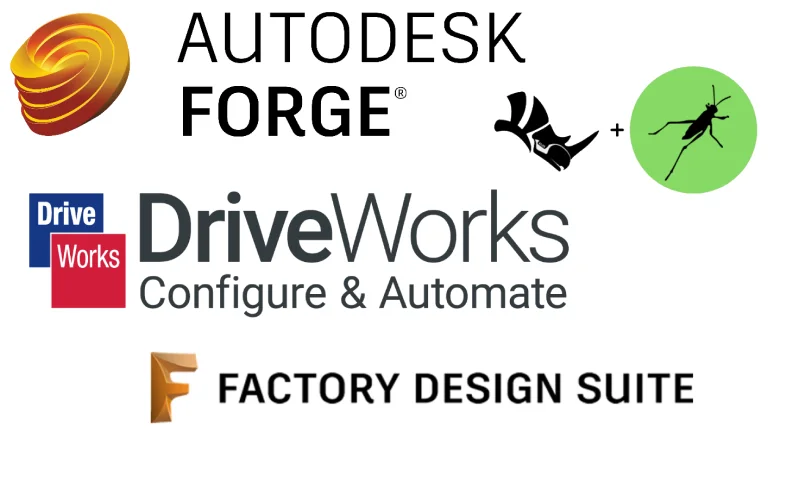

Our areas of expertise include the installation of the top 3D part automation programs in the market, including DriveWorks, VisualCAD/CAM, and Mastercam Automation Suite. Together with our experience, we can help companies to realize the entire potential of CAD and CAM automation, more productivity, and faster time to market. Get the next step of maximizing your CAD and CAM procedures. Consult with us today.

CAD Automations Development

We have different automations in our CAD automation service that facilitate the design processes and make them productive. We have the ability to parameterize design, inject standard components, template designs, as well as design rule checking. Certain functions, such as dimensioning and annotating, feature recognition, file management, design optimization, and data export, can also be automated. Indicatively, the generation of part numbers and Bills of Materials (BOM) is automated, which saves time and creates accuracy.

Programming languages we use include Python, VBA, C++, and JavaScript to create specifications and automations that meet the needs of our clients. We also specialize in the development of bespoke user interfaces (UI) to increase usability and efficiency. These UIs will make the automation processes easy to use and will be easily integrated into your existing CAD environment. Consult us to find out how we can automate your CAD processes, make them faster, more efficient, and less prone to errors.

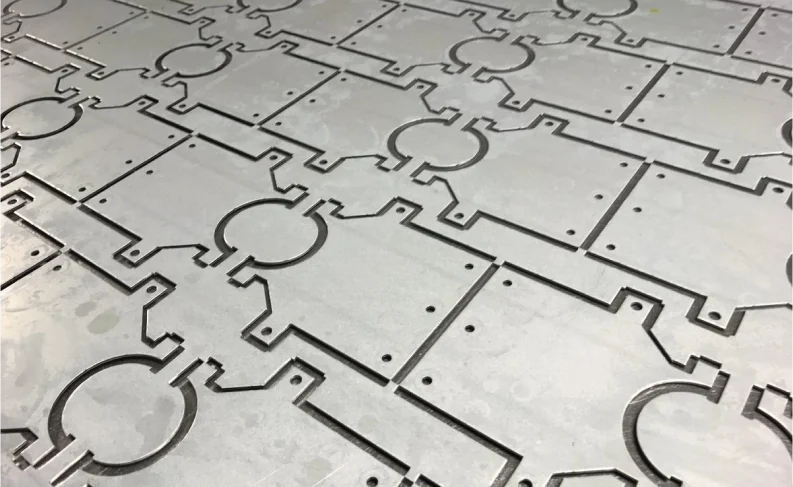

Nesting Automations Development

The development of nesting operations in furniture, sheet metal, and other industries requires fine-tuning to meet the needs of each of them. We are the masters of designing macros that will streamline the nesting operations, improve material efficiency, and reduce production costs.

Macros are ideal in the furniture industry to cut patterns of different woods and composites, taking into account various factors such as the grain direction, size of panel, and orientation of parts to ensure minimal waste and maximum use per sheet. In the case of sheet metal, our macros are concerned with nesting parts efficiently in order to minimize scrap and maximize the use of machines. We take factors such as the material thickness, bend allowances, and cutting tool constraints into consideration to produce the best nesting designs.

Our macros are flexible and are applicable in various industries such as the automobile, aerospace, and electronics. Bird nesting flat designs, 3D, and the complex assembly, whatever you need to accomplish it, our custom solutions can boost your productivity and profit margin.

CAM Automations Development

Our CAD CAM solutions are aimed at increasing efficiency and precision of manufacturing processes through the automation of repetitive tasks. Automations in CAM can facilitate the generation of toolpaths, minimize cutting paths, and minimize human errors during possible manual programming. They are created in programming languages such as Python, VBScript, and C++ and could be combined with the CAM software to design custom macros and scripts.

Indicatively, we can work on an automation to optimize toolpath strategies of complex 3D milling processes that minimize machine run time and material waste. We are focused on developing customized automations to meet the needs of our clients to enhance general productivity and quality. Through high automation of CAM, we will empower our clients to concentrate on what is vital in their projects at minimal operational costs of operation. See how our tailor-made CAM automation systems can be installed by your company to help in streamlining your production.

3rd Party Software Implementation

OEM and third-party developers of various CAD software have developed ready-to-use software to automate menial operations as well as to make them more economical in terms of designs. These are DriveWorks and iLogic. DriveWorks introduces an automatic design system that automates repeat design processes by creating custom design rules to design and create 3D models and drawings automatically with iLogic, introducing rule-based design automation to Autodesk Inventor, allowing the creation of intelligent models that update based on a set of preset logic.

We help clients to choose and use these tools in order to address their specific issues, to optimize processes, and to enhance the quality of work. When combined, these automation tools enable us to assist businesses to improve their productivity, minimising errors, and improve the accuracy of design. Get in touch with us to know how we can automate your CAD/CAM processes using custom automation solutions.

How it works

Step 01

Assessment

Your CAD and CAM processes are tested and analyzed by us to determine which areas can be automated to increase design and manufacturing efficiency. We are aware of the processes that are unique to your firm. This enables us to understand your objectives and issues that should be resolved.

Step 03

Solution Design & Presentation

We build a tailor-made automation strategy, choosing among the most effective CAD CAM 3D tools and technologies the ones that may address your particular needs. This could include either the creation of bespoke software or the use of 3 rd party software. We are offering our solution to you at affordable costs.

Step 05

Implementation

In implementation, we also enable the automation solution to be seamlessly integrated in your CAD and CAM environment, with your team members working with us to ensure that compatibility and minimal interferences occur. Performance optimization is done by thorough testing and adjustments.

Step 02

Requirement Gathering

We get specific requirements, such as specific CAD tasks, CAM workflows, and the desired results, and make the automation solution specific to your requirements.

Step 04

Development & Testing

Our automation scripts and systems are designed and extensively tested on CAD and CAM processes to ensure they are functional and in the way you want them to be. At this stage, we do User Acceptance Testing (UAT) to correct any UX and UI.

Step 06

Training and Support

We also offer extensive training of your personnel and continuous assistance to guarantee the optimality of utilization and upkeep of the CAD and CAM automation solution.

Project Highlights

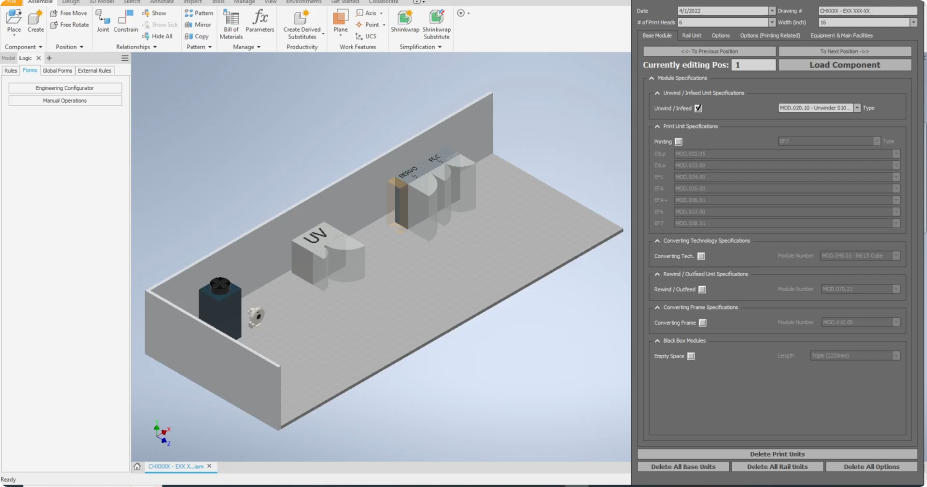

Our esteemed client from the Netherlands required automation to configure their complex, rule-based modular industrial printing machine for generating quotations and fulfilling orders.

Utilizing Autodesk Inventor and iLogic, we developed a 3D configuration tool with an intuitive UI, enabling users to systematically select the necessary units. The configurator accurately places the 3D models and calculates power and cooling requirements in Excel, determining the supporting equipment, such as chillers and power supplies, linked to the drawing. This automation reduced a manual 24-hour process to just 4 hours!

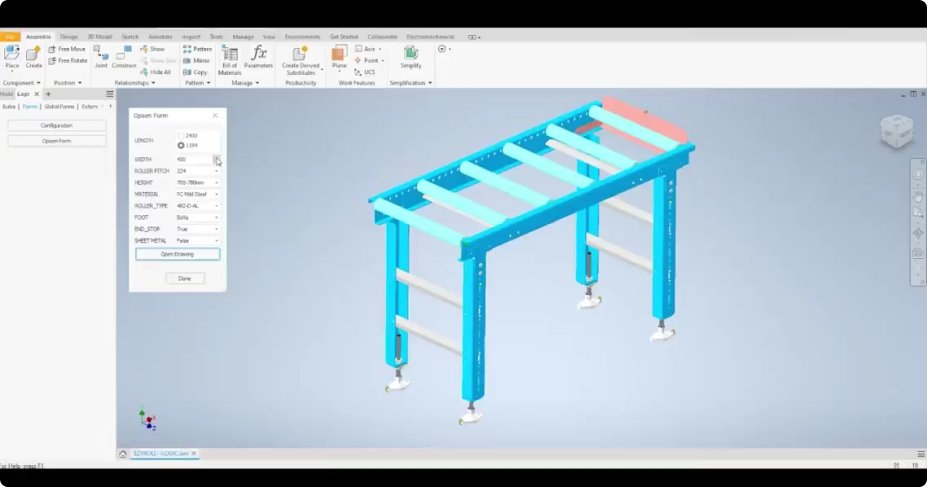

Our client, New Zealand’s largest manufacturer of conveyor components, tasked us with automating the configuration of their conveyor units and generating/updating the drawings automatically. Using the powerful iLogic for Autodesk Inventor, we developed a configuration tool with a simple UI that allows users to select different options and configurations for an individual conveyor, such as dimensions, rollers, stands, belt types, and more.

The configuration tool automatically generates the drawing for the specified conveyor, making cost estimates and sales quotations in just a few clicks. This configurator uses fully detailed engineering models and reduces the time required to just 20% of the semi-automatic process that preceded this development.

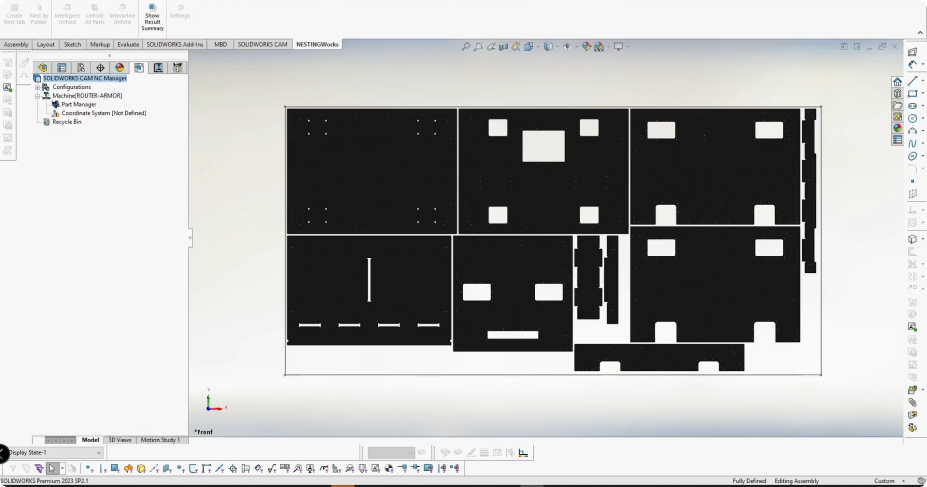

A consultation session with one of our clients to understand how their CAM processes could be made more efficient. That meant shadowing them digitally to better get an idea of the breakdown of time spent on various processes when preparing their parts.

The solution was to use macros to automatically complete those steps that were repetitive and were based on various inputs thus shrinking the time required to process parts during CAM process. Using macros we were able to reduce their 10 step process to 3 step process wherein the macro automatically completed the remaining 7 steps.

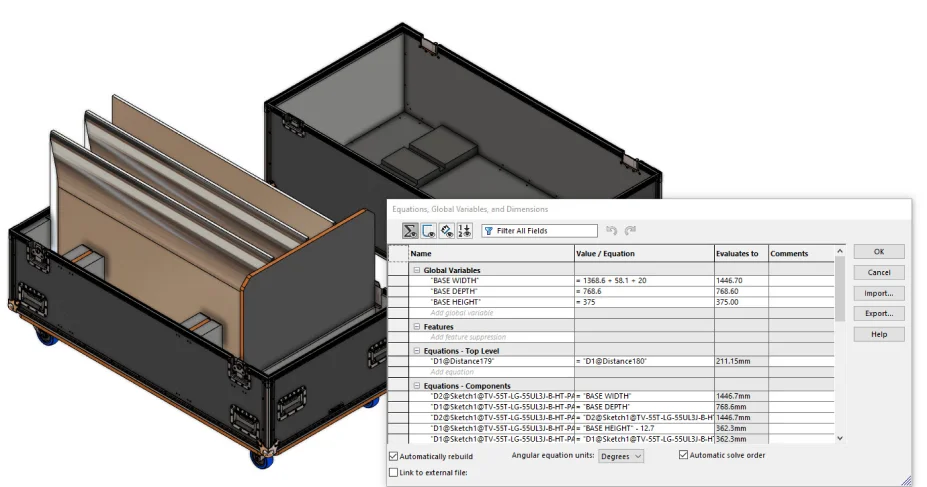

Understanding the clients needs for more efficient use of time to get preliminary CADs out for confirmation from the clients for production, we came up with re-usable skeleton CAD designs. This allows customers to see and understand what they would be ordering and give confirmation before detailing those designs to production stage. The result being faster quotes hence shortening the lead times for orders.

These CADs would then be re-used to cater to other client’s requests with similar needs. With para-metrically driven designs, even detail design can be modified in a nick of time to further save design costs.

Every industry that utilizes CAM processes spends a lot of time preparing the CAD for CAM. During our consultation, we understood the issues the client was facing and found a common denominator to all their steps required to recognize the various features their parts had.

Using the information, we developed custom solutions for their software to automatically recognize those repeated features hence drastically reducing the time to generate CNC codes for them to start manufacturing.

We understand the underlying principles of every business which is the maximize efficiency while increasing profit margins. This means every area that exists from concept to assembly requires to be efficient including CAD design.

For this reason we provide standardized libraries consisting for various hardware parts that can be re-used in different designs. This also allows us to program these parts such that once used, they automatically apply cutouts, rivets and fasteners in CAD system relieving designers of valuable time that could be spent on tackling multiple orders at the same time.