Conveyors and Material Handling

Comprehensive planning design and manufacturing data generation solutions, backed by years of experience, knowledge, continuous improvement and technology, targeted towards manufacturers and consulting contractors

Projects

100+

Hours Worked

8000+

Clients Served

5+

Overview

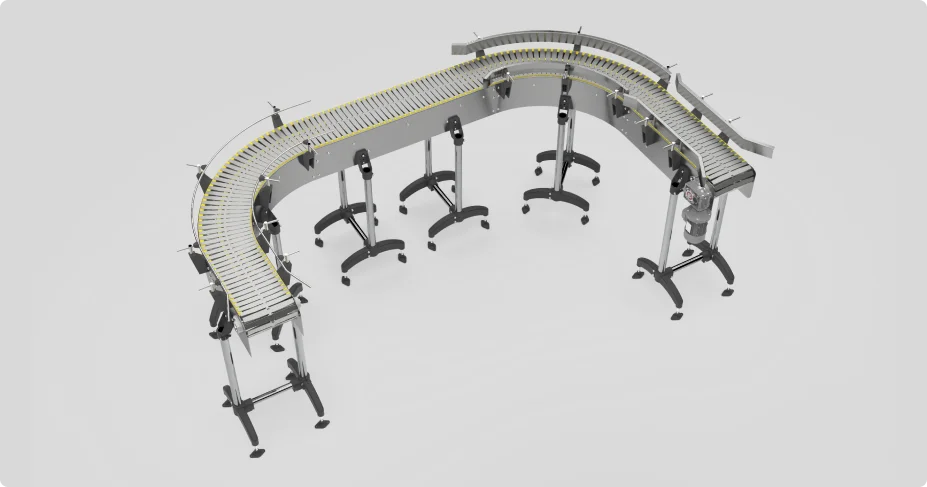

The conveyors industry is dynamic and demanding, requiring precision, efficiency, and innovative solutions. To address these needs, we offer a comprehensive solution tailored for both conveyors manufacturers and contracting firms involved in consulting and execution. Leveraging our extensive experience and expertise, we provide end-to-end support for large commissioning jobs, covering everything from initial cost estimation and planning to detailed design and implementation. Our expertise in conveyors spans a diverse range of industries, including logistics and warehousing, food processing, packaging and bottling, earth moving, and outdoor processing, among others

Our approach begins with the rapid and accurate generation of plans and drawings using advanced CAD tools, which aids in precise sales quotations and effective project pricing. We ensure clear and consistent communication with stakeholders to align on project goals and requirements. Once a project is confirmed, we focus on detailed design, producing 3D models, simulations, manufacturing drawings, CNC data, Bills of Materials, and O&M manuals. Our deep industry knowledge enables us to refine and innovate designs, adapting to the evolving material handling sector. We combine speed, accuracy, and expertise to deliver high-quality, reliable solutions that surpass industry expectations.

Our Expertise

Planning a large conveyors project entails managing intricate requirements and ensuring meticulous execution. Our solutions simplify this process by providing thorough support from inception to completion. We start by utilizing advanced CAD tools to swiftly create detailed plans and drawings, which form the foundation for accurate cost estimation and efficient project planning. This rapid generation of design documents allows for precise and competitive sales quotations, ensuring that project pricing reflects true costs and potential savings.

Use specialized CAD tools such as Autodesk Factory suite and Navisworks reduces the risk of errors and omissions. We emphasize clear and consistent communication with all stakeholders to ensure that project goals and specifications are aligned and fully understood. This collaborative approach helps in identifying and resolving potential issues early, optimizing the planning phase and setting the stage for a successful project execution.

We dive into detailed design, utilizing advanced CAD tools to produce precise 3D models that capture every aspect of the conveyor system. These models are crucial for visualizing the design, assessing spatial relationships, and identifying potential issues before fabrication begins.

We also conduct comprehensive simulations to analyze performance under various operational scenarios, ensuring that the design meets all functional requirements and performance standards. Our manufacturing drawings are meticulously crafted to provide clear, actionable instructions for production, while our CNC data ensures that components are machined with exacting precision.

Additionally, we generate detailed Bills of Materials (BOMs) to itemize all components, facilitating accurate procurement and cost management. Operation and Maintenance (O&M) manuals are provided to guide users in the proper operation, maintenance, and troubleshooting of the system.